-

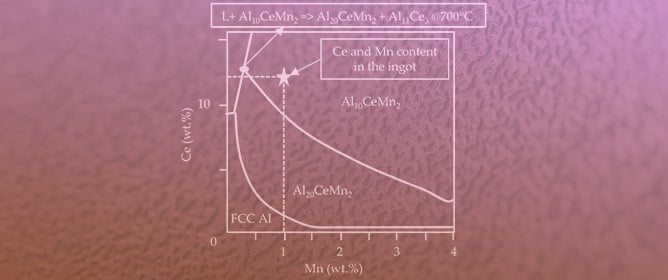

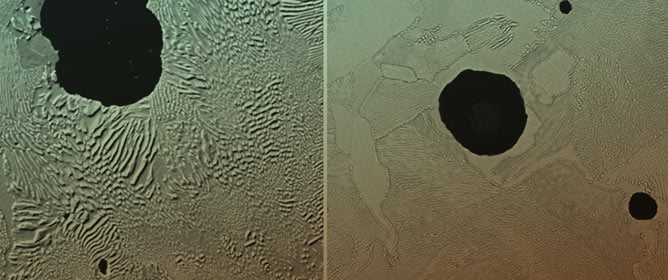

Solidification Kinetics of an Al-Ce Alloy with Additions of Ni and Mn

Solidification Kinetics of an Al-Ce Alloy with Additions of Ni and Mn -

Influence of Flow-Gas Composition on Reaction Products of Thermally Treated NMC Battery Black Mass

Influence of Flow-Gas Composition on Reaction Products of Thermally Treated NMC Battery Black Mass -

Determination of Corrosion Resistance of High-Silicon Ductile Iron Alloyed with Nb

Determination of Corrosion Resistance of High-Silicon Ductile Iron Alloyed with Nb -

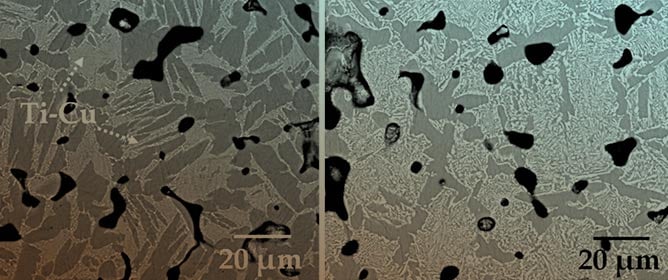

Powder Metallurgy Fabrication and Characterization of Ti6Al4V/xCu Alloys for Biomedical Applications

Powder Metallurgy Fabrication and Characterization of Ti6Al4V/xCu Alloys for Biomedical Applications -

Impact of Ti Doping on the Microstructure and Mechanical Properties of CoCrFeMoNi High-Entropy Alloy

Impact of Ti Doping on the Microstructure and Mechanical Properties of CoCrFeMoNi High-Entropy Alloy

Journal Description

Metals

Metals

is an international, peer-reviewed, open access journal published monthly online by MDPI. The Portuguese Society of Materials (SPM), and the Spanish Materials Society (SOCIEMAT) are affiliated with Metals and their members receive a discount on the article processing charges.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within Scopus, SCIE (Web of Science), Inspec, CAPlus / SciFinder, and other databases.

- Journal Rank: JCR - Q2 (Metallurgy & Metallurgical Engineering) / CiteScore - Q1 (Metals and Alloys)

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 15 days after submission; acceptance to publication is undertaken in 2.7 days (median values for papers published in this journal in the first half of 2023).

- Recognition of Reviewers: reviewers who provide timely, thorough peer-review reports receive vouchers entitling them to a discount on the APC of their next publication in any MDPI journal, in appreciation of the work done.

- Companion journals for Metals include: Compounds and Alloys.

Impact Factor:

2.9 (2022);

5-Year Impact Factor:

2.9 (2022)

Latest Articles

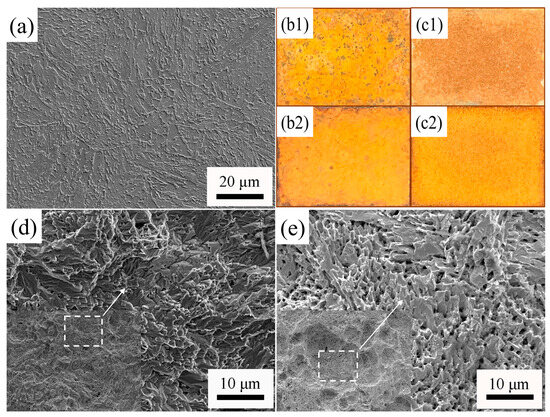

Influence of UV Illumination on the Corrosion Behavior of New 3Ni Weathering Steel in Marine Atmospheric Environments

Metals 2023, 13(9), 1543; https://doi.org/10.3390/met13091543 (registering DOI) - 01 Sep 2023

Abstract

We investigate the effect of pure darkness and UV illumination on the corrosion process of 3Ni weathering steels involved in both marine atmospheric environments. The corrosion behavior of 3Ni steel in both environments was assessed by cyclic acceleration experiments, electrochemical measurements, morphological analysis

[...] Read more.

We investigate the effect of pure darkness and UV illumination on the corrosion process of 3Ni weathering steels involved in both marine atmospheric environments. The corrosion behavior of 3Ni steel in both environments was assessed by cyclic acceleration experiments, electrochemical measurements, morphological analysis and physical phase analysis. The results show that UV illumination affects the corrosion process through the photovoltaic effect of the corrosion products, with photoelectrons and photo-vacancies participating in the redox reaction between the substrate and the atmospheric environment, thereby affecting the corrosion rate of 3Ni steel, the physical composition of the corrosion products and the denseness of the rust layer.

Full article

(This article belongs to the Topic Materials for Corrosion Protection)

►

Show Figures

Open AccessArticle

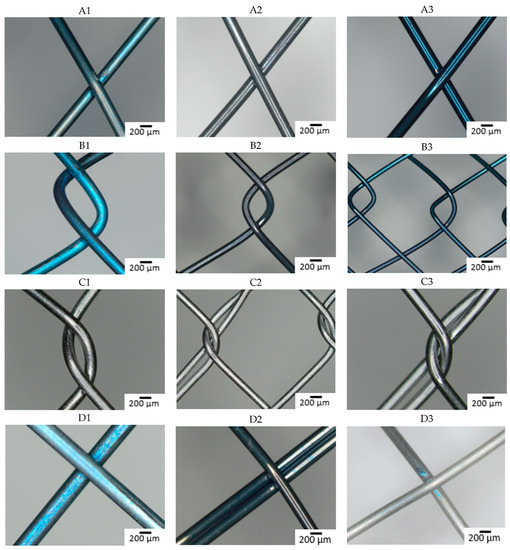

Influence of the Manufacturing Process on the Corrosion and Mechanical Behavior of Esophageal Stents

Metals 2023, 13(9), 1542; https://doi.org/10.3390/met13091542 (registering DOI) - 01 Sep 2023

Abstract

Esophageal nitinol stents are an established method for treating swallowing difficulties caused by obstructing cancer. This raesearch investigates the influence of different qualities of raw metal alloys in combination with production technology on corrosion resistance in standardized simulated gastric fluid (SGF). Four different

[...] Read more.

Esophageal nitinol stents are an established method for treating swallowing difficulties caused by obstructing cancer. This raesearch investigates the influence of different qualities of raw metal alloys in combination with production technology on corrosion resistance in standardized simulated gastric fluid (SGF). Four different international stent manufacturers produced samples of their standard stents from nitinol sourced from three different alloy manufacturers. The stents were subjected to a 6-week immersion in SGF. During the immersion, the surface was studied at specified intervals using microscopy. The surface of the samples was also studied by X-ray Photoelectron Spectroscopy and after immersion the released ions were analyzed. Results demonstrated that both raw material and certain steps in the manufacturing process negatively affect corrosion resistance. Analysis of the SGF showed that the amount of nickel released is proportional to the degree of corrosion attack. Finally, current accepted standard test methods are inadequate for assessing susceptibility to corrosion by gastric acid and should take the low pH of the implanted environment into account. Conversely, certain measures in the manufacturing process are able to reduce the impact of the base material on corrosion susceptibility.

Full article

(This article belongs to the Special Issue Advances in Stability of Metallic Implants)

►▼

Show Figures

Figure 1

Open AccessFeature PaperArticle

Creep Behavior and Deformation Mechanism of a Third-Generation Single Crystal Ni-Based Superalloy at 980 °C

Metals 2023, 13(9), 1541; https://doi.org/10.3390/met13091541 (registering DOI) - 01 Sep 2023

Abstract

As the primary choice for aero-engine turbine blades, creep resistance is an important mechanical property for the developing third-generation single crystal Ni-based superalloys. The creep behavior of the superalloy in the [001] orientation was studied at 980 °C under a series of stress

[...] Read more.

As the primary choice for aero-engine turbine blades, creep resistance is an important mechanical property for the developing third-generation single crystal Ni-based superalloys. The creep behavior of the superalloy in the [001] orientation was studied at 980 °C under a series of stress levels, accompanied with scanning electron microscope (SEM) and transmission electron microscope (TEM) observation to investigate the microstructure and deformation mechanism. The deformation mechanism of the alloy is found to be dislocation gliding, propagating and forming a dislocation network in the γ/γ′ interface. Dislocation networks could hinder the movement of dislocation and decrease the creep rate to a constant during the steady-creep stage. The formation of dislocation networks was analyzed due to the interaction of <110> {111} dislocations. Then dislocations cut into γ′ phases as individual <110> super-dislocations, anti-phase boundary dislocation pairs, and stacking faults. The <110> super-dislocation in the γ′ phase may cross-slip into the {001} plane from the {111} plane to form Kear–Wilsdorf locks, which could inhibit dislocations from gliding or cross-slipping and then enhance the creep resistance.

Full article

(This article belongs to the Special Issue High-Temperature Oxidation and Corrosion of Structured Materials)

►▼

Show Figures

Figure 1

Open AccessArticle

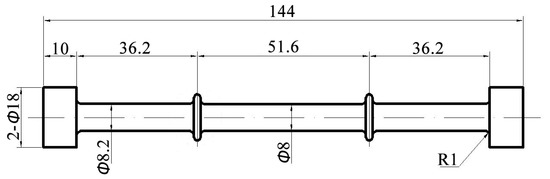

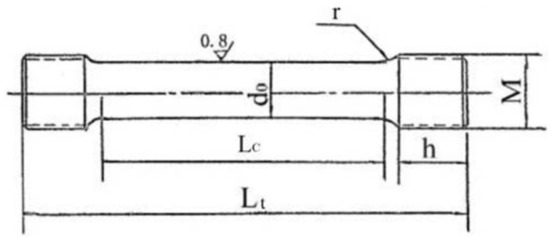

The Effect of Defect Characteristics on Prediction of Fatigue Life of TC4 Titanium Alloy Welded Joints

Metals 2023, 13(9), 1540; https://doi.org/10.3390/met13091540 - 31 Aug 2023

Abstract

The size and depth of defects significantly affect fatigue performance; the main purpose of this article is to clarify the effect of stress correction factors caused by defects on the fatigue life of α + β Type titanium alloy welded joints. In order

[...] Read more.

The size and depth of defects significantly affect fatigue performance; the main purpose of this article is to clarify the effect of stress correction factors caused by defects on the fatigue life of α + β Type titanium alloy welded joints. In order to investigate the fatigue characteristics of α + β Type titanium alloy welded joints, axial constant amplitude loading fatigue tests were performed with a stress ratio of −1. The test results show that the fatigue life continues to increase as the stress amplitude decreases, and the failure modes can be classified into two types: interior failure and surface failure. A fatigue parameter (λ) determined by both defect depth and size was proposed which allowed for a good generalization of the data point distribution in short and long-life regions. The stress correction factor (W) related to the S–N characteristics was constructed by combining the λ and average defect size, and it effectively improved the dispersion of the test data. Continuing, the fatigue life prediction model was established under the condition that the defect type and size can be estimated or detected on the basis of the dislocation energy method. The results indicated that the evaluated values of the new life model associated with W are in good agreement with the test results.

Full article

(This article belongs to the Special Issue Fatigue, Damage and Fracture of Metallic Materials)

►▼

Show Figures

Figure 1

Open AccessArticle

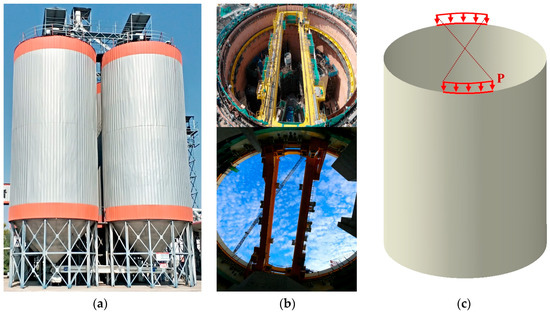

Localized Perturbation Load Approach for Buckling Design of Thin-Walled Steel Cylindrical Shells under Partial Axial Compression

Metals 2023, 13(9), 1539; https://doi.org/10.3390/met13091539 - 31 Aug 2023

Abstract

►▼

Show Figures

A thin-walled steel cylindrical shell is a common engineering structure that has an efficient load-carrying capacity. This structure is more easily subjected to partial axial compression loads in application, and buckling is the main failure mode. However, there are few available design methods

[...] Read more.

A thin-walled steel cylindrical shell is a common engineering structure that has an efficient load-carrying capacity. This structure is more easily subjected to partial axial compression loads in application, and buckling is the main failure mode. However, there are few available design methods for partial axially compressed steel cylindrical shells. Motivated by this, a design method called the localized perturbation load approach (LPLA) is proposed in this paper. The finite element framework for the application of LPLA is established. The location and number of perturbation loads are determined by considering the imperfection sensitivity and the buckling failure mode of partial axial compressed cylinders. A series of buckling experiments are carried out to validate the LPLA method. In addition, the reliability of LPLA for the design of cylindrical shells with different imperfection locations and dimensions is also verified. The results show that LPLA can give conservative and reliable lower-bound buckling loads. Therefore, LPLA can be used as a design method for thin-walled steel cylindrical shell structures under partial axial compression in actual engineering.

Full article

Figure 1

Open AccessArticle

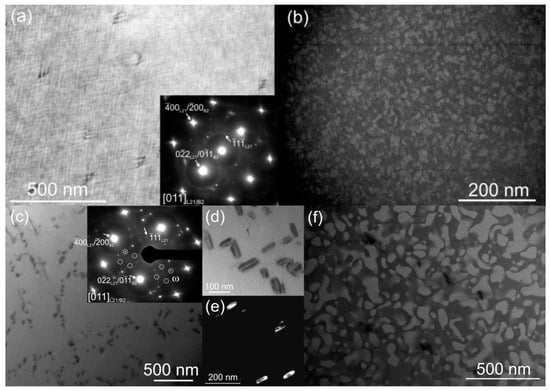

The Cyclic Stability of the Superelasticity in Quenched and Aged Ni44Fe19Ga27Co10 Single Crystals

Metals 2023, 13(9), 1538; https://doi.org/10.3390/met13091538 - 30 Aug 2023

Abstract

The effect of aging (at 773 K for 1 h) on the cyclic stability of superelasticity was studied in preliminarily quenched (after annealing at 1448 K for 1 h) Ni44Fe19Ga27Co10 [001]-oriented single crystals. It was shown

[...] Read more.

The effect of aging (at 773 K for 1 h) on the cyclic stability of superelasticity was studied in preliminarily quenched (after annealing at 1448 K for 1 h) Ni44Fe19Ga27Co10 [001]-oriented single crystals. It was shown that NiFeGaCo single crystals (both quenched and aged) exhibited highly stable superelasticity during more than 105 loading/unloading cycles in compression without destruction. The degradation of the superelasticity curves was divided into stages, and each stage of degradation was carefully considered. The precipitation of ω-phase particles led to a change in the degradation mechanism of superelasticity in the aged crystals. The main degradation mechanism for quenched crystals is a formation of uniform distribution of dislocations; for aged crystals, the microstructural degradation mechanisms consist of a non-uniform distribution of dislocations around the particles and the appearance of residual martensite.

Full article

(This article belongs to the Special Issue Metallic Functional Materials: Development and Applications)

►▼

Show Figures

Figure 1

Open AccessArticle

Simulation and Optimization of Shot Peening Process for CoCrFeNiAlx High-Entropy Alloy

Metals 2023, 13(9), 1537; https://doi.org/10.3390/met13091537 - 30 Aug 2023

Abstract

In this work, Ti-10V-2Fe-3Al alloy was selected as the test material, and the shot peening process of a CoCrFeNiAlx system high-entropy alloy was simulated based on effective test conditions, and the effects of dry shot peening and wet shot peening on the surface

[...] Read more.

In this work, Ti-10V-2Fe-3Al alloy was selected as the test material, and the shot peening process of a CoCrFeNiAlx system high-entropy alloy was simulated based on effective test conditions, and the effects of dry shot peening and wet shot peening on the surface properties were determined. Preliminary simulation results the surface of the test sample display a clear plastic deformation state that gradually diminishes and shifts towards the outermost layer. The stress transfer of the test sample gradually decreases, showing a gradient change, and the twin density also shows a random sample change. Then, the high-entropy alloy shot peening process was optimized, and the best process parameters were determined by analyzing the microhardness data, depth of action layer, and surface state. It was found that after wet shot peening, a new characteristic peak is generated, and with the increase in the size of the shot, its overall kinetic energy becomes increasingly higher, the strain energy of the material surface becomes increasingly higher, and the grain refinement is relatively high. This work provides a new approach to investigating the issues that are present during the shot peening process of CoCrFeNiAlx system high-entropy alloys.

Full article

(This article belongs to the Special Issue Finite Element Simulation of Mechanical Properties for Metallic Materials)

►▼

Show Figures

Figure 1

Open AccessReview

Laser Beam Machining of Titanium Alloy—A Review

Metals 2023, 13(9), 1536; https://doi.org/10.3390/met13091536 - 30 Aug 2023

Abstract

This study investigates the laser beam machining mechanism, surface formation mechanisms, heat-affected zone, taper formation, and the dimensional deviation of the titanium alloy, based on the information available in literature. The heat induced by the laser beam melts and vaporises titanium alloy, which

[...] Read more.

This study investigates the laser beam machining mechanism, surface formation mechanisms, heat-affected zone, taper formation, and the dimensional deviation of the titanium alloy, based on the information available in literature. The heat induced by the laser beam melts and vaporises titanium alloy, which is removed by a high pressure-assisted gas. The machined titanium alloy surface is expected to have craters and resolidified materials which were contributed by the low thermal conductivity of the titanium alloy. Taper and circularity error can be minimised by optimising the laser parameter, but it cannot be avoided in the laser beam machining of titanium alloy. Laser beam machining induces a non-diffusion phase transformation, which slightly changes the surface mechanical properties of the titanium alloys. Laser beam machining is gaining popularity as a way to improve the surface finish quality and properties of titanium components manufactured by additive manufacturing processes. To enhance the machining efficacy of titanium alloys, several hybrid machining processes were proposed.

Full article

(This article belongs to the Special Issue Advances in Titanium Alloys: Mechanical Properties, Microstructure and Ultrasonic Impact Treatment)

►▼

Show Figures

Figure 1

Open AccessArticle

Synergistic Effect of Alloying on the Strength and Ductility of High Carbon Pearlitic Steel

Metals 2023, 13(9), 1535; https://doi.org/10.3390/met13091535 - 30 Aug 2023

Abstract

In this work, the effects of the micro-alloying of Mn, Ni, and Si on the microstructure and mechanical properties of high-carbon pearlite steels were investigated. The results indicated that the addition of solely Ni to high-carbon pearlitic steel can enhance the strength through

[...] Read more.

In this work, the effects of the micro-alloying of Mn, Ni, and Si on the microstructure and mechanical properties of high-carbon pearlite steels were investigated. The results indicated that the addition of solely Ni to high-carbon pearlitic steel can enhance the strength through the refinement of interlamellar spacing, but work-hardening in the ferrite of the pearlite colony may be delayed, leading to a reduction in area. The multiple additions of Ni and the increase in Mn and Si contents in high-carbon pearlitic steel were beneficial to obtaining a balance between ultimate tensile strength and reduction in area. Three-dimensional atom probe tomography results showed Si partitioning into ferrite and Mn and Ni elements partitioning into cementite. The addition of Si inhibited the formation of a continuous network of grain-boundary cementite, leading to high strength and high ductility through optimization of the microstructure.

Full article

(This article belongs to the Special Issue Phase Transformation and Microstructure Characterization in Steels)

►▼

Show Figures

Figure 1

Open AccessArticle

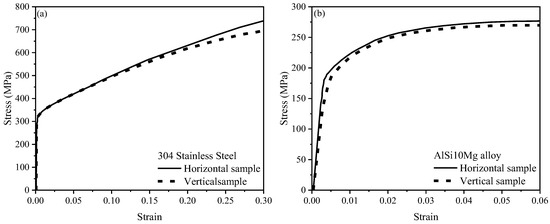

Ratcheting–Fatigue Damage Assessment of Additively Manufactured SS304L and AlSi10Mg Samples under Asymmetric Stress Cycles

Metals 2023, 13(9), 1534; https://doi.org/10.3390/met13091534 - 30 Aug 2023

Abstract

The present study aims to investigate the interaction of ratcheting and fatigue phenomena for additively manufactured (AM) samples of SS304L and AlSi10Mg undergoing uniaxial asymmetric stress cycles. Overall damage was accumulated through fatigue and ratcheting on AM samples prepared from three-dimensional-printed plates along

[...] Read more.

The present study aims to investigate the interaction of ratcheting and fatigue phenomena for additively manufactured (AM) samples of SS304L and AlSi10Mg undergoing uniaxial asymmetric stress cycles. Overall damage was accumulated through fatigue and ratcheting on AM samples prepared from three-dimensional-printed plates along vertical and horizontal directions. Fatigue damage was evaluated based on the strain energy density fatigue approach and ratcheting damage was calculated through use of an isotropic–kinematic hardening framework. The isotropic description through the Lee–Zavrel (L–Z) model formed the initial and concentric expansion of yield surfaces while the Ahmadzadeh–Varvani (A–V) kinematic hardening rule translated yield surfaces into the deviatoric stress space. Ratcheting of AM samples was simulated using finite element analysis through use of triangular and quadrilateral elements. Ratcheting values of the AM samples were simulated on the basis of Chaboche’s materials model. The predicted and simulated ratcheting damage curves placed above the experimental fatigue–ratcheting experimental data while predicted fatigue damage curves collapsed below the measured values. The overall damage was formulated to partition damage weights due to fatigue and ratcheting phenomena.

Full article

(This article belongs to the Special Issue Microstructure and Properties of Metallic Materials Produced by Additive Manufacturing)

►▼

Show Figures

Figure 1

Open AccessArticle

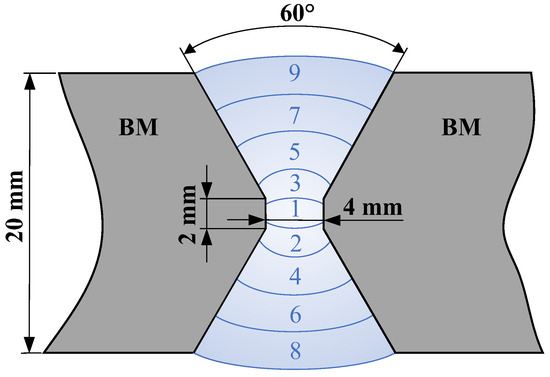

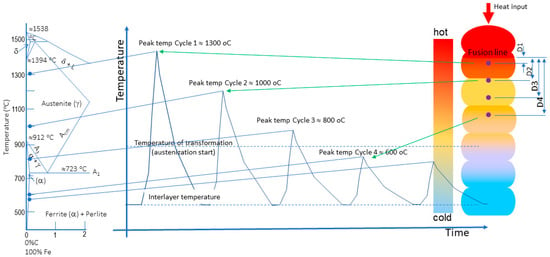

Proposal and Assessment of a Multiple Cycle-Continuous Cooling Transformation (MC-CCT) Diagram for Wire Arc Additive Manufacturing of Thin Walls

by

, , , , , and

Metals 2023, 13(9), 1533; https://doi.org/10.3390/met13091533 - 29 Aug 2023

Abstract

Continuous cooling transformation (CCT) diagrams of base metals are common in welding. They can be built using physical or numerical simulations, each with advantages and limitations. However, those are not usual for weld metal, considering its variable composition due to the dilution of

[...] Read more.

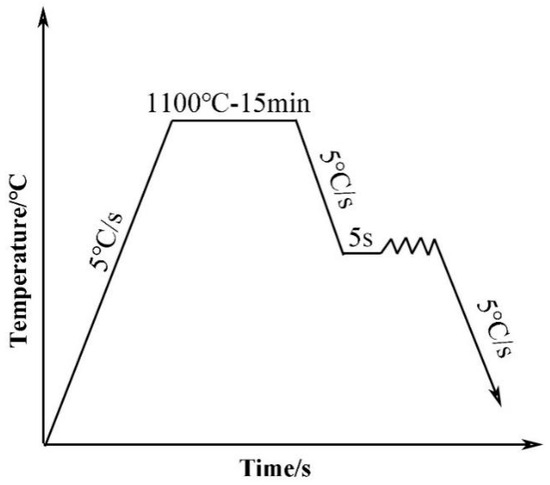

Continuous cooling transformation (CCT) diagrams of base metals are common in welding. They can be built using physical or numerical simulations, each with advantages and limitations. However, those are not usual for weld metal, considering its variable composition due to the dilution of the weld into the base metal. Wire Arc Additive Manufacturing (WAAM) is a distinctive case in which the interest in materials comparable with weld composition raises attention to estimating their mechanical properties. Notwithstanding, this concept is still not used in WAAM. Therefore, the aim of this work was to address a methodology to raise MC-CCT (Multiple Cycle Continuous Cooling Transformation) diagrams for WAAM by combining physical and numerical simulations. A high-strength low-alloy steel (HSLA) feedstock (a combination of a wire and a shielding gas) was used as a case study. To keep CCT as representative as possible, the typical multiple thermal cycles for additive manufacturing thin walls were determined and replicated in physical simulations (Gleeble dilatometry). The start and end transformations were determined by the differential linear variation approach for each thermal cycle. Microstructure analyses and hardness were used to characterise the product after the multiple cycles. The same CCT diagram was raised by a commercial numerical simulation package to determine the shape of the transformation curves. A range of austenitic grain sizes was scanned for the curve position matching the experimental results. Combining the experimental data and numerically simulated curves made estimating the final CCT diagram possible.

Full article

(This article belongs to the Special Issue Directed Energy Deposition of Metal Alloys)

►▼

Show Figures

Figure 1

Open AccessArticle

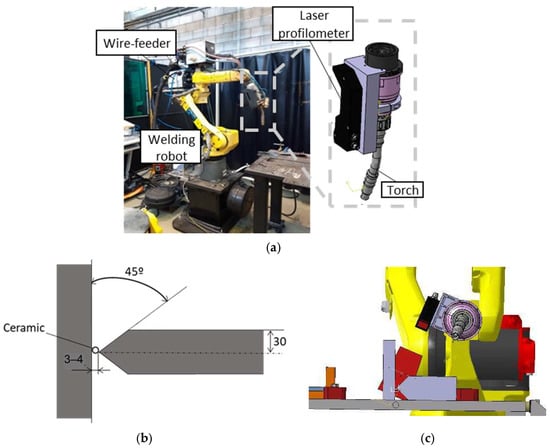

Intelligent and Adaptive System for Welding Process Automation in T-Shaped Joints

Metals 2023, 13(9), 1532; https://doi.org/10.3390/met13091532 - 29 Aug 2023

Abstract

The automation of welding processes requires the use of automated systems and equipment, in many cases industrial robotic systems, to carry out welding processes that previously required human intervention. Automation in the industry offers numerous advantages, such as increased efficiency and productivity, cost

[...] Read more.

The automation of welding processes requires the use of automated systems and equipment, in many cases industrial robotic systems, to carry out welding processes that previously required human intervention. Automation in the industry offers numerous advantages, such as increased efficiency and productivity, cost reduction, improved product quality, increased flexibility and safety, and greater adaptability of companies to market changes. The field of welding automation is currently undergoing a period of profound change due to a combination of technological, regulatory, and economic factors worldwide. Nowadays, the most relevant aspect of the welding industry is meeting customer requirements by satisfying their needs. To achieve this, the automation of the welding process through sensors and control algorithms ensures the quality of the parts and prevents errors, such as porosity, unfused areas, deformations, and excessive heat. This paper proposes an intelligent and adaptive system based on the measurement of welding joints using laser scanning and the subsequent analysis of the obtained point cloud to adapt welding trajectories. This study focuses on the optimization of T-joints under specific welding conditions and is intended as an initial implementation of the algorithm, thus establishing a basis to be worked on further for a broader welding application.

Full article

(This article belongs to the Special Issue Feature Papers in Welding & Joining)

►▼

Show Figures

Figure 1

Open AccessArticle

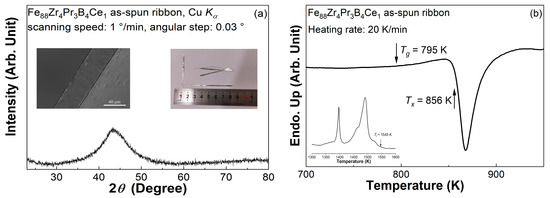

Effect of Minor Ce Substitution for Pr on the Glass Formability and Magnetocaloric Effect of a Fe88Zr4Pr4B4 Metallic Glass

by

, , , , , , , and

Metals 2023, 13(9), 1531; https://doi.org/10.3390/met13091531 - 29 Aug 2023

Abstract

In the present work, Fe88Zr4Pr3B4Ce1 metallic glass (MG) was successfully prepared by minor Ce substitution for Pr, and compared with Fe88Zr4Pr4B4 MG in terms of glass forming

[...] Read more.

In the present work, Fe88Zr4Pr3B4Ce1 metallic glass (MG) was successfully prepared by minor Ce substitution for Pr, and compared with Fe88Zr4Pr4B4 MG in terms of glass forming ability (GFA), magnetic and magnetocaloric properties. The GFA, Tc and the maximum magnetic entropy change (−ΔSmpeak) of the Fe88Zr4Pr3B4Ce1 MG were found to decrease slightly. At the same time, the possible interaction mechanism of minor Ce replacing Pr was also explained. The critical exponents (β, γ and n) obtained by the Kouvel–Fisher method indicate that Fe88Zr4Pr3B4Ce1 MG near Tc exhibits typical magnetocaloric behavior of fully amorphous alloys. The considerable maximum magnetic entropy change (−ΔSmpeak = 3.84 J/(kg × K) under 5 T) near its Curie temperature (Tc = 314 K) as well as RCP (~ 646.3 J/kg under 5 T) make the Fe88Zr4Pr3B4Ce1 MG a better candidate as a component of the amorphous hybrids that exhibit table-shape magnetic entropy change profiles within the operation temperature interval of a magnetic refrigerator.

Full article

(This article belongs to the Special Issue Magnetic Properties Analysis of Amorphous and Partially Crystallized Alloys)

►▼

Show Figures

Figure 1

Open AccessArticle

Insight into the Role of Mo Content on the Microstructure and Impact Toughness of X80 Thick-Walled Low-Temperature Pipeline Steel

Metals 2023, 13(9), 1530; https://doi.org/10.3390/met13091530 - 29 Aug 2023

Abstract

►▼

Show Figures

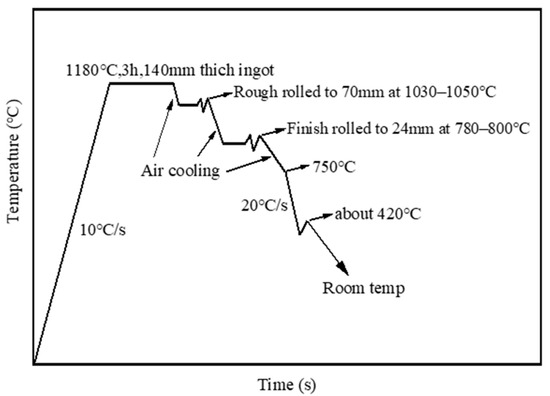

In this manuscript, the effects of Mo content on the microstructure and impact toughness of X80 thick-walled low-temperature pipeline steel were studied. Two test steels with different Mo content (0.25% and 0.40%) were prepared by the thermo-mechanical control process. The impact properties were

[...] Read more.

In this manuscript, the effects of Mo content on the microstructure and impact toughness of X80 thick-walled low-temperature pipeline steel were studied. Two test steels with different Mo content (0.25% and 0.40%) were prepared by the thermo-mechanical control process. The impact properties were measured at −45 °C, and the microstructure evolution was observed via an optical microscope (OM), a scanning electron microscope (SEM), electron back-scattered diffraction (EBSD), and a transmission electron microscope (TEM). Each steel showed the formation of a mixed microstructure consisting of polygonal ferrite (PF), granular bainite (GB), and lath bainite (LB). Increasing Mo content resulted in the rise of LB at the expense of PF and GB. At the same time, the morphology of martensite/austenite (M/A) constituents changed from blocky to slender. The dislocation density in the ferrite matrix around the M/A constituents enhanced with an increase in Mo content. This also led to an increase in the microstrains around the M/A constituents. Also, the number fraction of the high angle grain boundary (HAGB) (MTA > 15°) decreased with the addition of more Mo content. Furthermore, with an increase in Mo content from 0.25% to 0.40%, the low-temperature impact toughness decreased from 206 to 57 J. Both an increase in the slender M/A constituents and a decrease in the HAGB number fraction deteriorated the low-temperature impact toughness of the X80 thick-walled low-temperature pipeline steel.

Full article

Figure 1

Open AccessArticle

Study on Joining for Thin-Walled Aluminum Alloy/Steel Tubes by Electromagnetic Flanging Process

Metals 2023, 13(9), 1529; https://doi.org/10.3390/met13091529 - 29 Aug 2023

Abstract

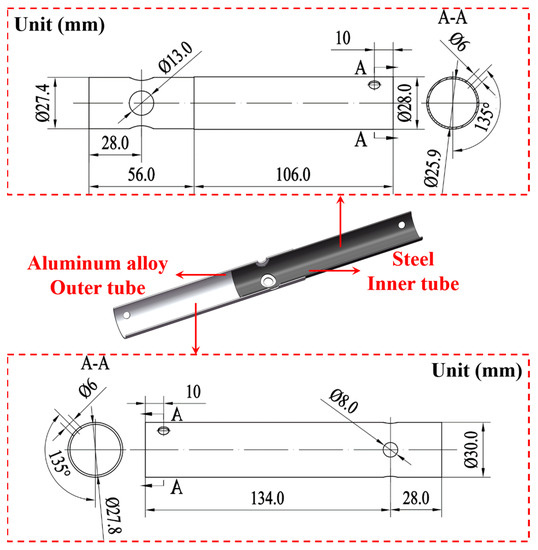

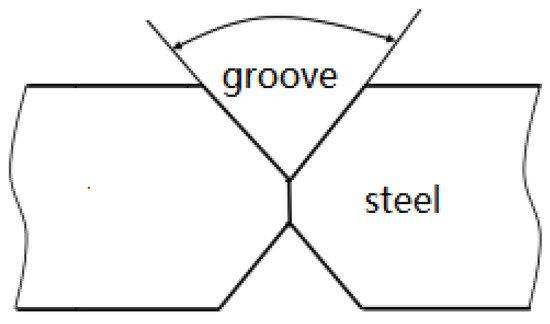

A structure for joining thin-walled 6061-T6 aluminum alloy tube (outer tube) and Q195 steel tube (inner tube) by electromagnetic flanging process was proposed. The formation process, mechanical properties, failure modes, and morphology of the joint were investigated. The results showed that the outer

[...] Read more.

A structure for joining thin-walled 6061-T6 aluminum alloy tube (outer tube) and Q195 steel tube (inner tube) by electromagnetic flanging process was proposed. The formation process, mechanical properties, failure modes, and morphology of the joint were investigated. The results showed that the outer tube impacted the inner tube, the flanges of the prefabricated holes on the outer tube were embedded into the prefabricated holes of the inner tube under the action of Lorentz force, and thus the mechanical locking joint was obtained. There were two tensile failure modes for the joints: Pull-out and fracture. Specifically, when the discharge energy was relatively high, the failure mode changed from pull-out to fracture. Combining the results of tensile tests and morphology observations, the maximum loads of the joints increased with the discharge energy. However, excessive discharge energy would lead to the brittle fracture of the inner tube, which was not beneficial to the service. Better discharge energy and the maximum load of the joint at this discharge energy were obtained.

Full article

(This article belongs to the Special Issue Research Progress on Joining Dissimilar Material)

►▼

Show Figures

Figure 1

Open AccessArticle

Corrosion Performance of Welded Joints for E40 Marine Steel

Metals 2023, 13(9), 1528; https://doi.org/10.3390/met13091528 - 28 Aug 2023

Abstract

Marine steel requires excellent toughness and corrosion resistance in a low-temperature seawater environment. In this study, corrosion tests on E40 steel were performed, including electrochemical testing of the weld metal and heat-affected zone, dynamic corrosion testing in a simulated seawater environment, and the

[...] Read more.

Marine steel requires excellent toughness and corrosion resistance in a low-temperature seawater environment. In this study, corrosion tests on E40 steel were performed, including electrochemical testing of the weld metal and heat-affected zone, dynamic corrosion testing in a simulated seawater environment, and the analysis and comparison of results obtained using different methods. The corrosion resistance of E40 was determined by measuring the saturation current density of the anodic dissolution of the steel in a corrosive medium by an electrochemical method. Under laboratory conditions, the corrosion resistance was investigated under simulated seawater. The results showed that regions with uneven microhardness corresponded to the inhomogeneity of the corrosion potential, with measured fluctuations of up to 40 mV. Nanoscale corrosive–aggressive non-metallic inclusions served as a substrate for the deposition of titanium and niobium carbonitrides, thereby weakening the corrosion resistance. The corrosion rate of the base metal was 1.16–1.64 mm/year, which was slightly higher than that of the heat-affected zone. The influence of deposition on the corrosion performance of welded joints under different deoxygenation processes was studied, and the deposition composition was controlled by a deoxygenation process to improve the corrosion resistance of the steel plate.

Full article

(This article belongs to the Special Issue Thermodynamic Properties of Metallurgical Melts)

►▼

Show Figures

Figure 1

Open AccessArticle

Evolution of Recrystallization Texture in A286 Iron-Based Superalloy Thin Plates Rolled via Various Routes

Metals 2023, 13(9), 1527; https://doi.org/10.3390/met13091527 - 28 Aug 2023

Abstract

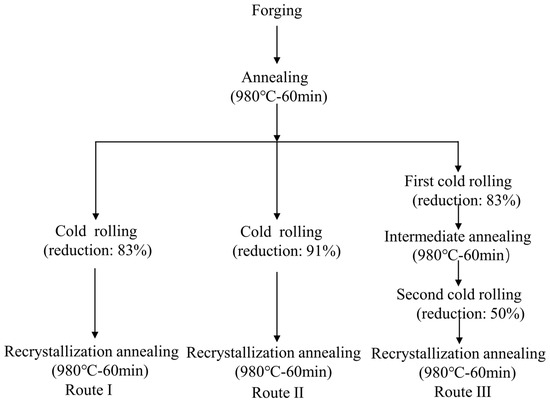

The A286 iron-based superalloy has wide-ranging applications in replacing expensive nickel-based and cobalt-based superalloy to manufacture the turbine disk as well as the pipelines and valves of the fourth-generation supercritical water reactor (SCWR) working below 650 °C. The recrystallization texture importantly affects the

[...] Read more.

The A286 iron-based superalloy has wide-ranging applications in replacing expensive nickel-based and cobalt-based superalloy to manufacture the turbine disk as well as the pipelines and valves of the fourth-generation supercritical water reactor (SCWR) working below 650 °C. The recrystallization texture importantly affects the mechanical properties and oxidation resistance of superalloys. However, very few investigations are available on the recrystallisation texture of A286 alloy. The current work reports the texture of A286 alloy fabrication using various rolling routes, including one-stage cold rolling with the rolling rates of 83% (Route I) and 91% (Route II), and two-stage cold rolling with the rolling rate of 83% + 50% (Route III). Route III is preferentially recommended to manufacture A286 alloy thin plates due to the obviously reduced work hardening as well as the weakened recrystallization texture and anisotropy; moreover, compared with other routes, the recrystallized grain size of Route III did not significantly coarsen. We also revealed the mechanism for the effect of cold rolling textures on the final recrystallization texture and the role of the deformation twin in {110} <115> grain. In this study, recrystallization texture develops through two independent mechanisms related to different deformation microstructures, including the recrystallization texture inherited from deformation texture and the recrystallization texture depended on deformation twins.

Full article

(This article belongs to the Special Issue Microalloying in Ferrous and Non-ferrous Alloys)

►▼

Show Figures

Figure 1

Open AccessArticle

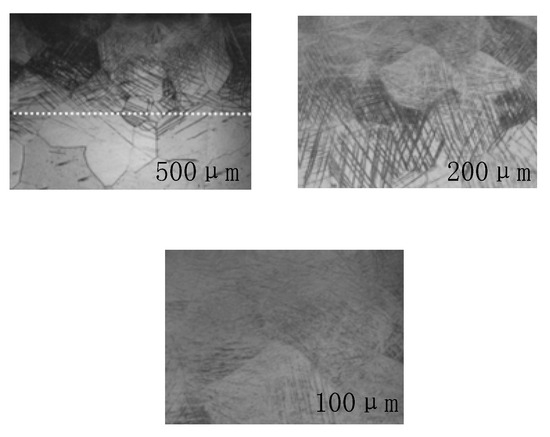

Analysis on the Key Parameters to Predict Flow Stress during Ausforming in a High-Carbon Bainitic Steel

Metals 2023, 13(9), 1526; https://doi.org/10.3390/met13091526 - 28 Aug 2023

Abstract

Since flow stress is an important parameter in the processing and application of metallic materials, it is necessary to trace the flow stress during austenite deformation. Thermal compression deformation of austenite in a high-strength bainitic steel was conducted using a Gleeble-3500 thermo-mechanical simulator,

[...] Read more.

Since flow stress is an important parameter in the processing and application of metallic materials, it is necessary to trace the flow stress during austenite deformation. Thermal compression deformation of austenite in a high-strength bainitic steel was conducted using a Gleeble-3500 thermo-mechanical simulator, within the deformation temperature range of 400 °C~900 °C. By analyzing the stress–strain curves and strain-hardening exponent, the effects of strain hardening and dynamic recovery on the dislocation density of the material during the thermal processing were considered in the present work. Based on the general form of the Kocks–Mecking–Estrin (KME) model, the effects of deformation temperature and strain on the key parameters of the model were clarified. Differing from other work which commonly terms m (strain rate sensitivity exponent) and k2 (dimensionless parameters for dynamic recovery) as constants, the current models consider the quantitative relationship between key parameters and deformation temperature and strain. The results show that m is an exponential function related to temperature and strain, which decreases with the increase in strain. Meanwhile, k2 is a temperature-dependent polynomial function that increases as the deformation temperature increases. Finally, a modified constitutive KME model was proposed to predict the austenitic plastic stress with strain. Using established m-ε and k2-T models, the predicted curves are in good agreement with the experimental measurements.

Full article

(This article belongs to the Special Issue Advanced High-Strength Bainite Steels)

►▼

Show Figures

Figure 1

Open AccessArticle

Microstructure and Performance Research on Ceramic-Enhanced Inconel 718 Matrix Composite Using Laser Additive Manufacturing

Metals 2023, 13(9), 1525; https://doi.org/10.3390/met13091525 - 28 Aug 2023

Abstract

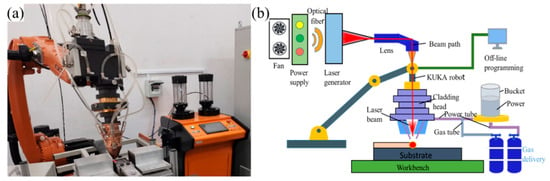

This article presents a 95% IN718 + 5% (75% Cr2O3 + TiO2) ceramic coating on the SS316L substrate surface with laser additives. The macro shape, phase, microstructure, interface, wear resistance and tensile resistance of metal base composite materials

[...] Read more.

This article presents a 95% IN718 + 5% (75% Cr2O3 + TiO2) ceramic coating on the SS316L substrate surface with laser additives. The macro shape, phase, microstructure, interface, wear resistance and tensile resistance of metal base composite materials are analyzed. The results show that metal matrix composite (MMC) laminated composite materials have good microscopic hardness and wear resistance compared to single materials. Comparative analyses with single IN718 materials indicate that the laminated composite materials exhibit superior microscopic hardness and wear resistance. Additionally, the study reveals a positive correlation between material hardness and wear resistance, characterized by reduced wear coefficient and average abrasion with increased material hardness. The findings of this research offer a cost-effective and practical method for producing high-resistance coating layer composite materials.

Full article

(This article belongs to the Special Issue Metal Composite Materials and Their Interface Behavior)

►▼

Show Figures

Figure 1

Open AccessReview

Cladding Failure Modelling for Lead-Based Fast Reactors: A Review and Prospects

Metals 2023, 13(9), 1524; https://doi.org/10.3390/met13091524 - 28 Aug 2023

Abstract

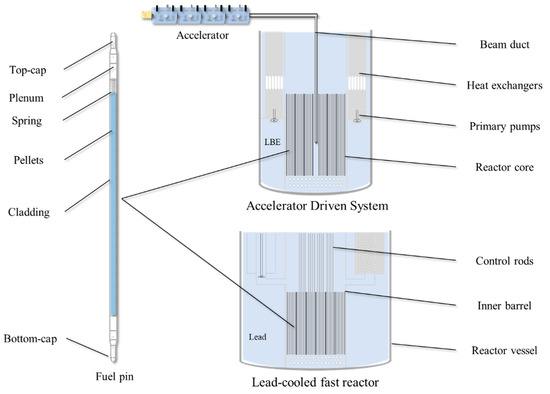

Lead-cooled fast reactors (LFRs) are considered one of the most promising technologies to meet the requirements introduced for advanced nuclear systems. LFRs have higher neutron doses, higher temperatures, higher burnup and an extremely corrosive environment. The failure studies of claddings play a vital

[...] Read more.

Lead-cooled fast reactors (LFRs) are considered one of the most promising technologies to meet the requirements introduced for advanced nuclear systems. LFRs have higher neutron doses, higher temperatures, higher burnup and an extremely corrosive environment. The failure studies of claddings play a vital role in improving the safety criteria of nuclear reactors and promoting research on advanced nuclear materials. This paper presented a comprehensive review of the extreme environment in LFRs based on the fuel performance analyses and transient analyses of reference LFRs. It provided a clear image of cladding failure, focusing on the underlying mechanisms, such as creep, rupture, fatigue, swelling, corrosion, etc., which are resulted from the motions of defects, the development of microcracks and accumulation of fission products to some extent. Some fundamental parameters and behavior models of Ferritic/Martensitic (F/M) steels and Austenitic stainless (AuS) steels were summarized in this paper. A guideline for cladding failure modelling was also provided to bridge the gap between fundamental material research and realistic demands for the application of LFRs.

Full article

(This article belongs to the Special Issue Analysis and Prediction of Mechanical Properties of Metallic Materials under Extreme Environment)

►▼

Show Figures

Figure 1

Journal Menu

► ▼ Journal Menu-

- Metals Home

- Aims & Scope

- Editorial Board

- Reviewer Board

- Topical Advisory Panel

- Photography Exhibition

- Instructions for Authors

- Special Issues

- Topics

- Sections

- Article Processing Charge

- Indexing & Archiving

- Editor’s Choice Articles

- Most Cited & Viewed

- Journal Statistics

- Journal History

- Journal Awards

- Society Collaborations

- Conferences

- Editorial Office

Journal Browser

► ▼ Journal BrowserHighly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Topic in

Applied Sciences, Coatings, JMMP, Materials, Metals

Welding and Joining of Materials in Off-Shore and Energy Industry

Topic Editors: Dariusz Fydrych, Jacek Tomków, Aleksandra Świerczyńska, Grzegorz Rogalski, Sergey G. Parshin, Chandan Pandey, Michał Landowski, Hamed Aghajani Derazkola, Thomas HasselDeadline: 15 September 2023

Topic in

Applied Sciences, Coatings, CMD, Materials, Metals

Environmental Sensitivity and Safety Assessment of Materials

Topic Editors: Jian Chen, Daokui Xu, Fanjiang Meng, Jamie NoëlDeadline: 30 September 2023

Topic in

Applied Sciences, Coatings, Materials, Metals, Nanomaterials

Cutting-Edge Research Trends in (Non)Metallic Materials: Design, Testing and Application

Topic Editors: Petrica Vizureanu, Andrei Victor Sandu, Madalina Simona Baltatu, Dumitru Doru Burduhos NergisDeadline: 31 October 2023

Topic in

AI, Alloys, Applied Sciences, Materials, Metals

Hybrid Computational Methods in Materials Engineering

Topic Editors: Wojciech Sitek, Jacek Trzaska, Imre FeldeDeadline: 30 November 2023

Conferences

Special Issues

Special Issue in

Metals

Effect of Ultrasound on the Structure and Properties of Metallic Materials

Guest Editor: Ayrat NazarovDeadline: 15 September 2023

Special Issue in

Metals

New Trends in Fatigue of Metals

Guest Editors: Luis Reis, Pedro MoreiraDeadline: 30 September 2023

Special Issue in

Metals

Advances in Additive Manufacturing of Ti-Based Alloys: Processing and Simulation

Guest Editor: Menachem BambergerDeadline: 10 October 2023

Special Issue in

Metals

Phase Transformations and Physical Properties of Alloys

Guest Editor: Louisa MeshiDeadline: 31 October 2023